Light and Strong Hollow Door Core

1.What are the common materials for door core?

As is well known to all,a wooden door is made of many components:door stile,door core,door skin, door rails,door mould and locks.Door core refers and bears much beauty and strength,sometimes with fire rated property.People use different kinds of door core to meet their own demands,and to show their ideas for indoor decorations.In some cases,door is a key part for the luxury designs and upper level social status,which is quite amazing.

Before choosing your good-looking door, you need to know some about what is inside of the door. Here are the common materials for door core, and each has its own features:

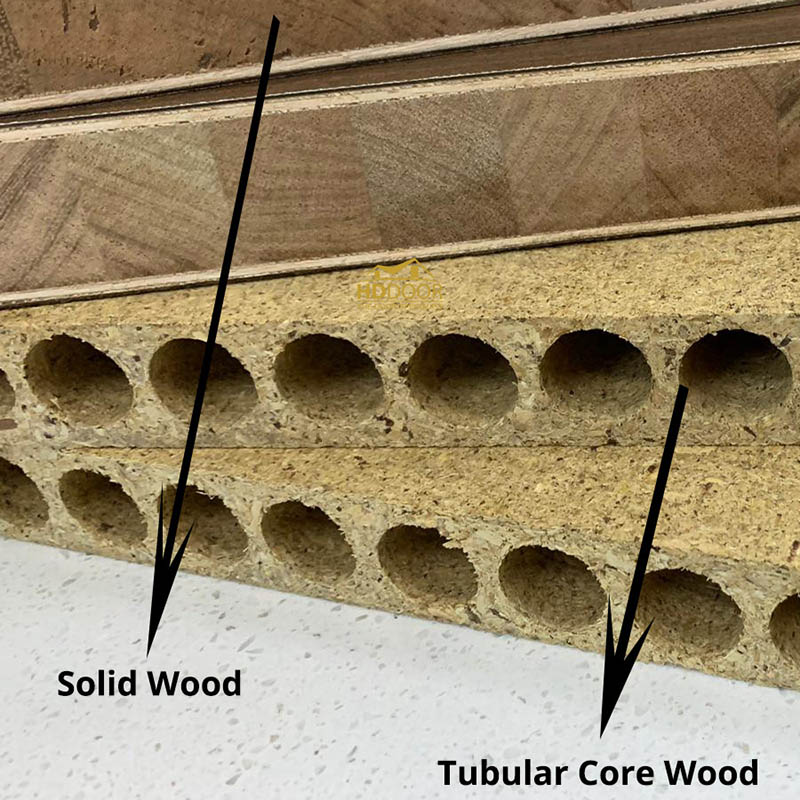

1. Solid door core. There are some precious wood for making door core, like Oak, Cherry and so on, which are very heavy and high density. They show very beautiful grains and colors after carving. Some pines, like radiata pine from New Zealand and white pine from Latvia, are also used for door core. Particle board is a good and common solid door core, often with fire-proof features. All the solid door core are very heavy, and in high-density.

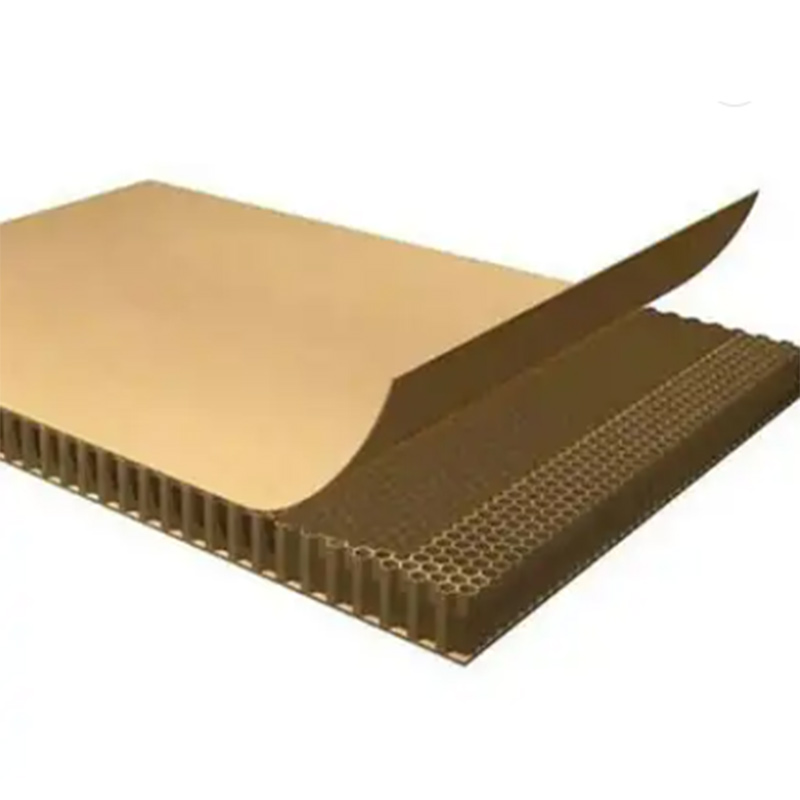

2. Hollow door core. This refers to add tubes or spaces in door core materials under modern technology. As most have ever seen, hollow particle board and pine wood are among the popular series. Another is honeycomb paper.

3. Foam and others. They are often used for cheap and short time projects.

2.Why hollow particle board?

Hollow door core has many excellent characteristics, especially in weight. We list the unique features as follows.

1. Weight reduction. Density of solid wood and solid particle board are often over 700kg/m³, while hollow particle board with that of 320kg/m³. This will reduce nearly 60% weight.

2. Eco-friendly glue and raw materials. We use China poplar or radiata pine wood as raw materials, and standard E1 glue. Wood logs are firstly chipped into particles, then dried and glued. After that, they will become harden with pressure and heat.

3. Sound insulation. Because there many tubes and spaces in door core, it shows some sound proof features.

3.Key parameters

Shandong Xing Yuan offers a set of hollow particle board for door core. Please check the following chart.

| Raw materials | China poplar or pine |

| Thickness available | 24/26/28/30/33/35/38/40mm |

| Size available | 1180*2090mm,900*2040mm |

| Glue grade | Standard E1 glue |

| Density | 320 kg/m³ |

| Production method | Vertical extrusion and heated |

| Packing method | Export pallet packing |

| Capacity | 3000 sheets per day |

4.Goods Show